Field Services

Pipe support Field Survey

To avoid costly damage and operational breakdown, the regular inspection of thermal movement in piping systems and the condition of supports - especially in older installations - is widely encouraged. Our engineers will do following inspection and produce comprehensive reports and provide the appropriate recommendations for a solution.

- Hot Inspection – (In Plant operation)

- Cold Inspection – (In shut condition)

- Inspection of Pipe displacement

Installation and commissioning

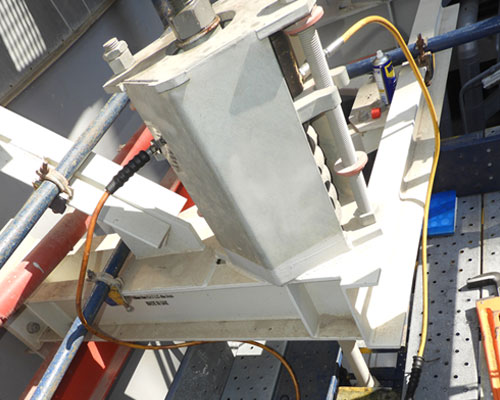

Most mistakes in piping supports are made during installation and commissioning. Our engineers will supervise

- Installation of pipe supports at pre-determined position

- Replacement of old supports with new supports

- Inspect the system for correct installation according to drawings

- Deblocking and commissioning the Pipe supports according to the procedures

- Inspection of load and travel after commissioning

- Inspect for freedom of movement of the pipe system in all three planes

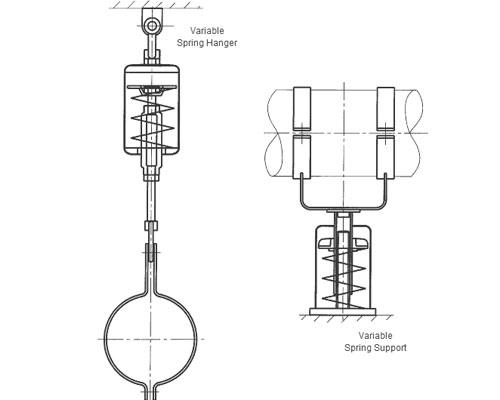

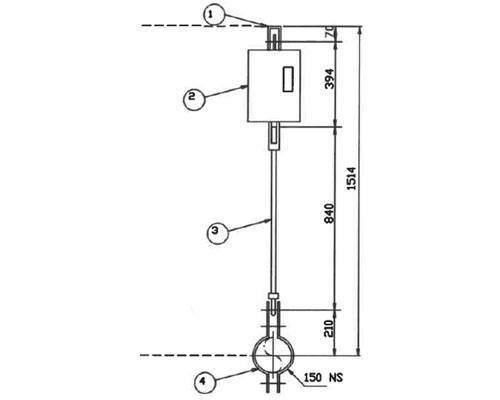

Testing and Calibration of Hangers at Site

Our engineers will also calibrate variable and constant spring hangers supports at site Using load cells to ensure the performance of the hangers (if required).

Inspection of Snubbers

We do Inspection on all kinds of snubbers and all brands and produce comprehensive reports and provide the appropriate recommendations for a solution.

Pipe Vibration Monitoring

Background

Piping vibration problems are a reality at Oil and Gas, Refinery, Petrochemical, Power and Steel plants. Facility owners are extremely sensitive to these integrity risks because of the significant consequences associated with product releases from ruptured piping.

What is Piping Vibration,

Piping Vibration is simply the movement of pipe away from its static, at-rest position. Some vibration can be seen by the naked eye, some vibration can be felt or heard, and some vibration occurs only occasionally under certain operating conditions and may not be recognized until a piping failure has occurred.

What we do,

To secure the ideal solution for a vibration problem, a detailed engineering evaluation is necessary. As well as general consulting, Pipe supports Services offers the On-site measurement of vibration through which the type and root cause can be determined.

We conduct Risk-based assessments thru our International partners and an International partner has unique experience and skills in Piping vibration, including the assessment of large scale piping projects.

In addition to this we offer installation supervision or a complete installation service using our international partner.

Engineering

Apart from Inspection, Maintenance and Installation Services, We offer Engineering services that provides,

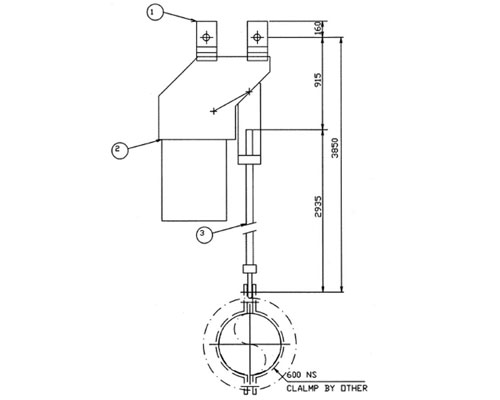

- Selection of Pipe supports according to project

- Planning of supports

- Preparation of Pipe supports drawings (2D – AutoCAD)

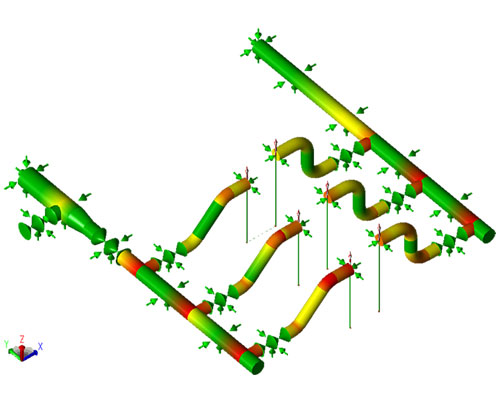

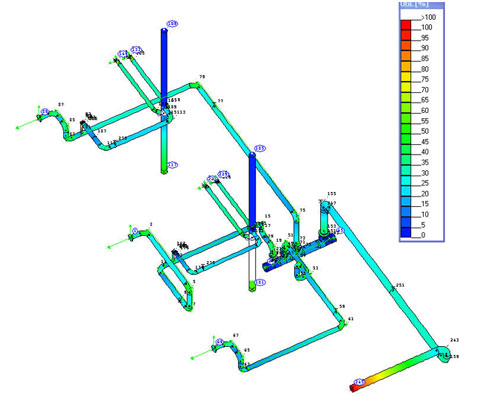

- Pipe stress Analysis

- FEA